Cutoff

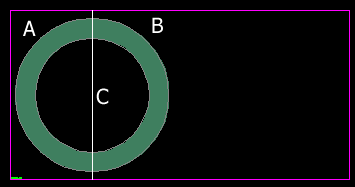

The "Cutoff" command is used to divide a sheet into one or several portions.

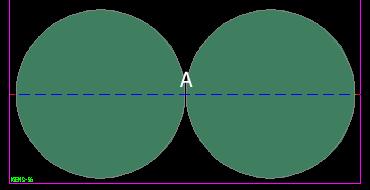

In the image above, the sheet needs to be "cutoff" into two portions (A) and (B). To do this make a line or a polyline (C) that describes the cutoff geometry. Start the command and select the cutoff object (C).

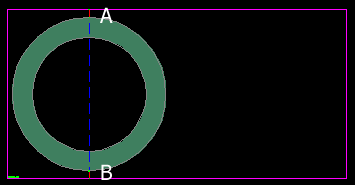

The command will cut off the sheet at point (A) and (B) below. It will not destroy the internal geometry of the part.

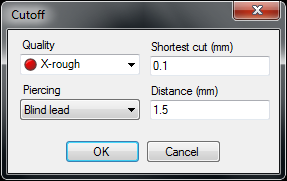

Quality

Since the cutoff is only used for separation the X-rough cutting quality may be used to make the fastest cut.

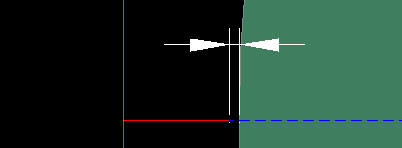

Piercing

The "Blind lead" is sufficient in most cases. Otherwise, use the lead of your choise.

Shortest cut

There will only be a cut made if the length of the cut is longer that this value. In the image above, the distance between the two parts at point (A) is too short so no cutting will be done there.

Distance

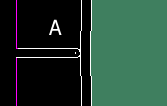

This value controls the distance between the parts, the center of the starts and the end of the cutoffs. Setting the distance to more than 1.5 times tool diameter leaves a small bridge between the cutting paths (A).

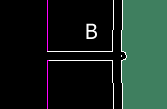

If the parts are located on the machine when the machine cuts the toolpath and the value is a smaller distance value than the tool radius the parts are destroyed (B).

Different methods

There are three different methods to use the "Cutoff":

Cutoff first

Do the cutoff first and then cut the parts on the sheet. Be sure the distance value is large enough to not destroy the parts. In this case run the cutoff first in the Order command.

Cut part first

Cut all parts first and then the cutoff. If the parts are not unloaded from the machine be sure the distance value is large enough. In this case run the cutoff at the end in the Order command.

Cut part first, unload and then cut

To first cut and then unload all parts set the distance value to zero. In this case there will be no bridges.