Order

If cutting only one part or if the cutting order between parts is not important, then skip this command and use the "Process" command directly. Prepare parts before starting.

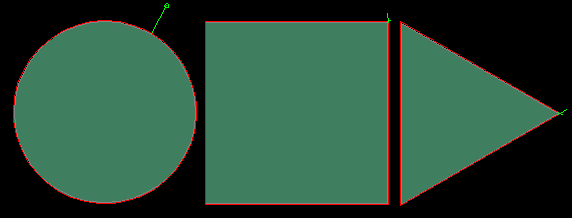

Start a new drawing and create three parts in the form of a disk, square and a triangle. Add toolpath.

Start the "Order" command.

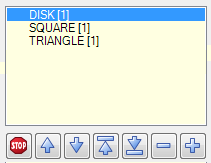

The following is shown:

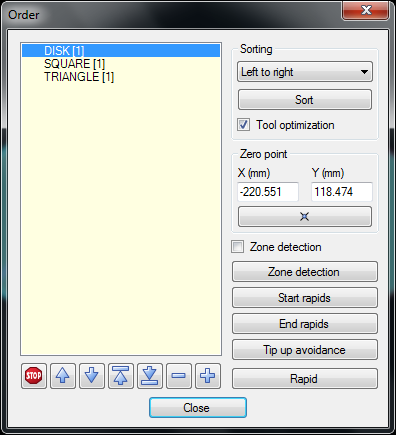

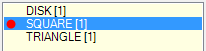

Select the parts. The following window is shown:

What does the number in parentheses after the part name mean?

This is the tool number that will be used to cut the part.

Manual adjustment of the cut order

The list shows the cutting order of the parts. The DISK will be cut first and the TRIANGLE will be the last part cut. To change the cutting order use the "arrow" buttons to move the parts up or down. To remove or add parts to the cut order use the "plus" or "minus" buttons.

Stop between parts

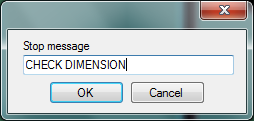

Use the "Stop" button to add a program stop in front of the parts. If the machine supports "stops" then there will be a program stop just before this part is cut.

If the machine supports the feature to give a message to the machine operator, then the message can be a helpful hint.

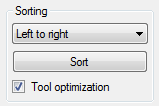

Pre-defined cutting orders

When cutting many parts use pre-defined methods to set up the cut order. The result of the "strategies" depends on the quantity and geometry of the parts and sheets.

Select a strategy from the drop down list and press the "Sort" button to sort the cut order in the following ways:

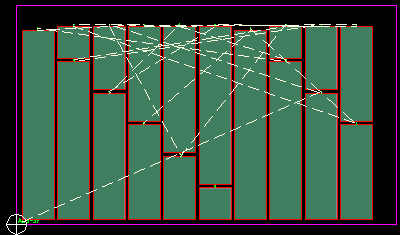

Closest

This method looks from the start point to the next closest point and then to the next closest point again and so on. If optimizes the order to avoid long movements at the end.

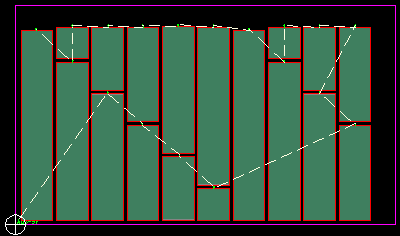

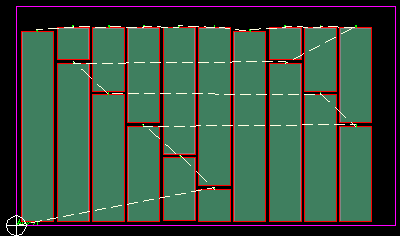

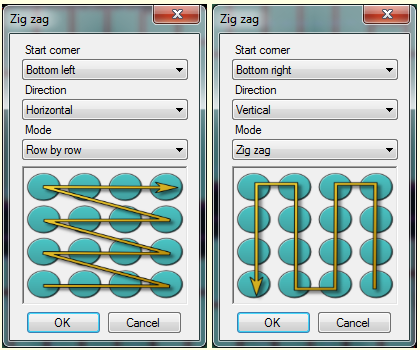

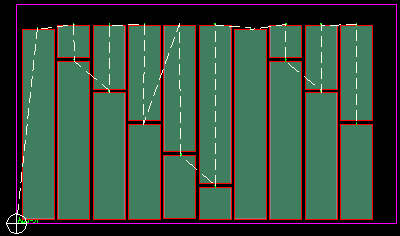

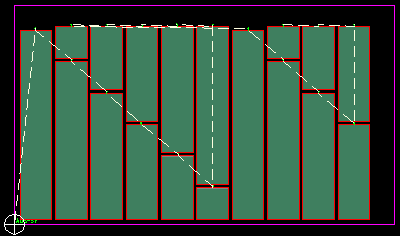

Zig zag

This method has different sub-settings:

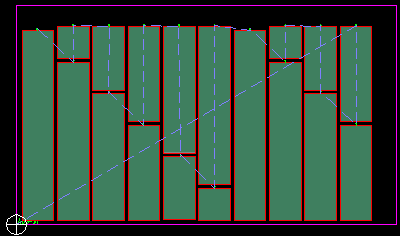

Left to right

This method starts with the most left part and ends with the most right parts.

Right to Left

This method starts with the most right part and ends with the most left part.

As placed

This method takes the parts in the order they have been placed on the sheet.

This method is mostly used together with other applications.

Manual

Use this method to select the parts in the order they should be cut.

Spread

This method takes the parts randomly and not close to each other. The method is mostly used by Plasma cutting machines to spread the heat out over the whole sheet.

Tool optimization

This example uses only one tool. If a machine is equipped with several tools then this feature is useful since it keeps parts together that use the same tools resulting in less tool changes.