Common cutlines

The "Common cutlines" command is used for separating parts with only one cut. This cutting method is much faster than traditional cutting. The following settings are common for all methods:

Tool radius compensation (kerf)

Common cutline generates a toolpath without kerf information. The coordinates in the CNC-file always describe the center position of the jet.

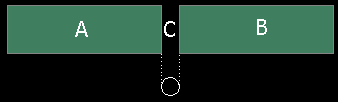

Relation between part distance and tool diameter

The tool center is located between the parts to be separated.

It is important that the distance between the parts are the same as the dimension of the jet. If the distance between the parts (C) is closer then no toolpath are generated between the parts. If the parts have a larger distance then (A) and (B) will be cut separately and the (C) portions will be cut two times. The tolerances for the distance are approximately plus/minus 0.01 to 0.05 millimeters.

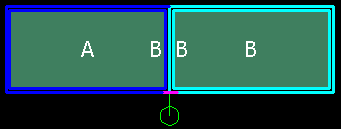

Cutting quality

The cutting quality is inherited from the parts. When cutting between two parts that have different cutting quality the toolpath which is common for the part will have the best quality.

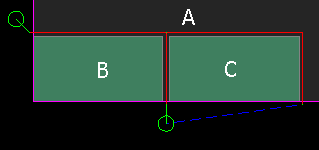

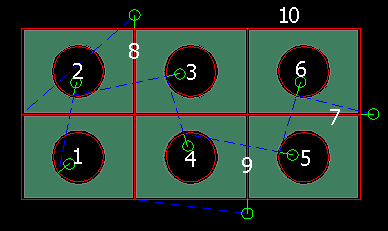

Trim to sheet

If the tolerance of a part is not critical, save time by using the edge of the sheet as the edge of the part.

To use this, the parts must be nested close to the edge of the sheet. Check the "Trim to sheet" box.

Mix between normal cutting and sheetwise

When internal geometries already have a toolpath the command will skip these holes. Cut holes with another command before using the common cut.